- Browse Categories

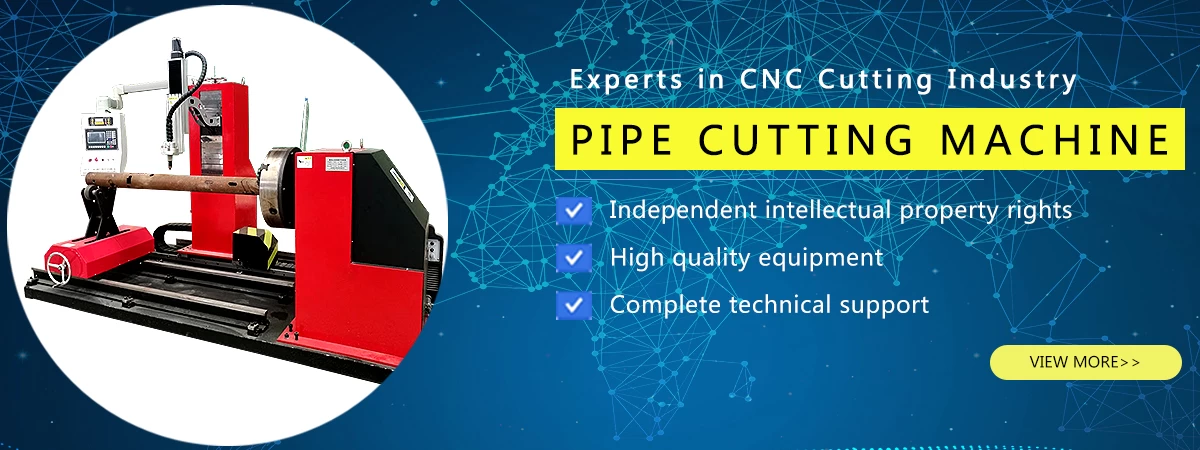

- steel plate with pipe machine

- Table model cutting machine

- steel gantry cutting machine

- fiber laser cutting machine

- Multi-head cutting machine

- Portable Cutting Machine

- Subscribe

-

Get email updates on new products

- Certifications

-

- Contact Us

-

Tel: 0086 (0)27 87969255

Fax: 0086 (0)27 87413947

Whatsapp/wechat: 86 18064016480

Skype: berylxu1

E-mail: berylxu@kingcutting.com

- New Product

- News

-

-

Differences between the stepper and servo

Differences between thestepper and servo There is no qualityproblem on the domestic motor in CNC plasma cutting machine, and the precisionis the same ... -

difference between domestic laser machine and imported laser machine

Differences between domestic laser cuttingmachine and imported laser cutting machine The laser cutting machine is invented bywestern country, so many ... -

Introduction of Laser Technology

The AnalyticApplication and Introduction of Laser Technology When applying to thecutting, the laser technology provides very excellent cutting quality... -

How to choose and use plasma source

How to choose and use plasma source How to choose a most suitable plasma source is extremelyimportant for cutting quality,cutting speed,cutting effici... -

Guidline for portable type choice

Guidance for thePortable (Mini) CNC Cutting Machine Model Selection Nowadaysthere are many portable CNC cutting machine manufacturers in China, making... -

The Processing Standard and Power Supply Principle

The Processing Standardand Power Supply Principle The kerf processed by a high quality CNCplasma cutting machine should be with the following characte... -

Fiber Laser Cutting Machine

Brief Introduction ofFiber Laser Cutting Machine 1. Advantagesof fiber laser cutting machine 1.1 Excellentlaser beam quality: light spot is smaller... -

Indian Customers Visited Our Company

Indian CustomersVisited Our Company After a longtime preparation, our two Indian customers visited our company successfullyyesterday. After a ... -

Thailand customer visits our factory

Thailand customer Alex Visit our factory December 162019, the French group Delachaux Group Thailand Company Alex visited our company. This visit, ... -

How to choose right model cnc cutting machine

http://www.plasmacuttersupplier.com/index.html How to choose right model cutting machine To choose a most suitable CNC cutting machine,we need to cons...

-

- Follow us

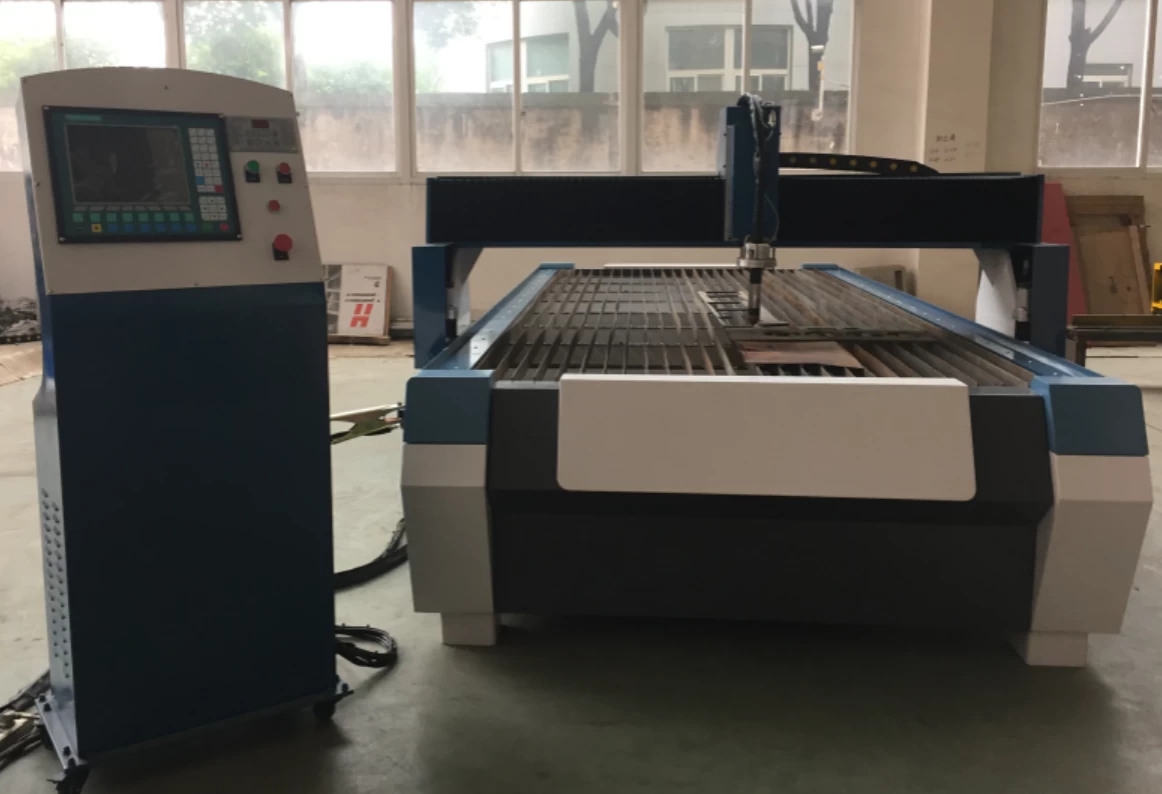

hot selling stainless steel high quality king cutting table plasma cutter factory

- *.This machine adopts integral structure,making installation easier and more reliable

- *.This machine adopts double-side driving to make torch does longitudinal movement followed straight tracks.The light design of crossbeam has a good rigidity,light self-weight and good stability of movement.

- *..The machine is equipped with water tank type dust-removing equipment,in order to achieve environmental protection requirement;a smoking type dust-removing equipment also can be applied according to the customer's needs.

- *.The machine is suitable to high-speed cutting thin sheet made of stainless steel,aluminium sheet and nonferrous metals etc.additionally,it also has able to cutting thick plate.

- *.The machine is widely applied for sheet-metal working,auto parts,wind turbines,and steel mould industries etc.

http://www.plasmacuttersupplier.com/about-us.html

hot selling stainless steel high quality king cutting table plasma cutter factory

Specifications:

- Bench model, plasma, flame, both plasma and flame cutting machine

- Bench structure, Y axis uses dual-motor dual-driven system, X, Y, Z axes all use dual straight rail that make the machine driving smoothly with high precision.

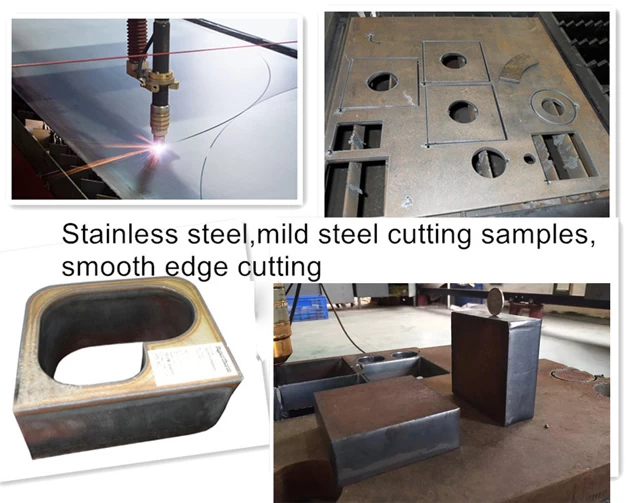

- The kerf is small, tidy and avoid a second dressing processing.

- It can apply to iron sheet, the aluminum sheet, the galvanized sheet, hardened steel plates, and metal plates and so on.

- The numerical control system disposes high, the automatic striking arc, the performance is stable.

- Support Wentai, Australia Fastcam, Germany IBE Software, FreeCAM software, produce standard G code format documents, also can change software to read AUTO CAD software produce DXF format documents. The control system uses the U disk to exchange processing document, easy to operate.

| Item | Parameters |

| Input voltage | 220v, 50HZ |

| Rated Power | 500-1000w |

| Brand | KingCutting or OEM |

| Machine dimension | 3700*2300*1500mm |

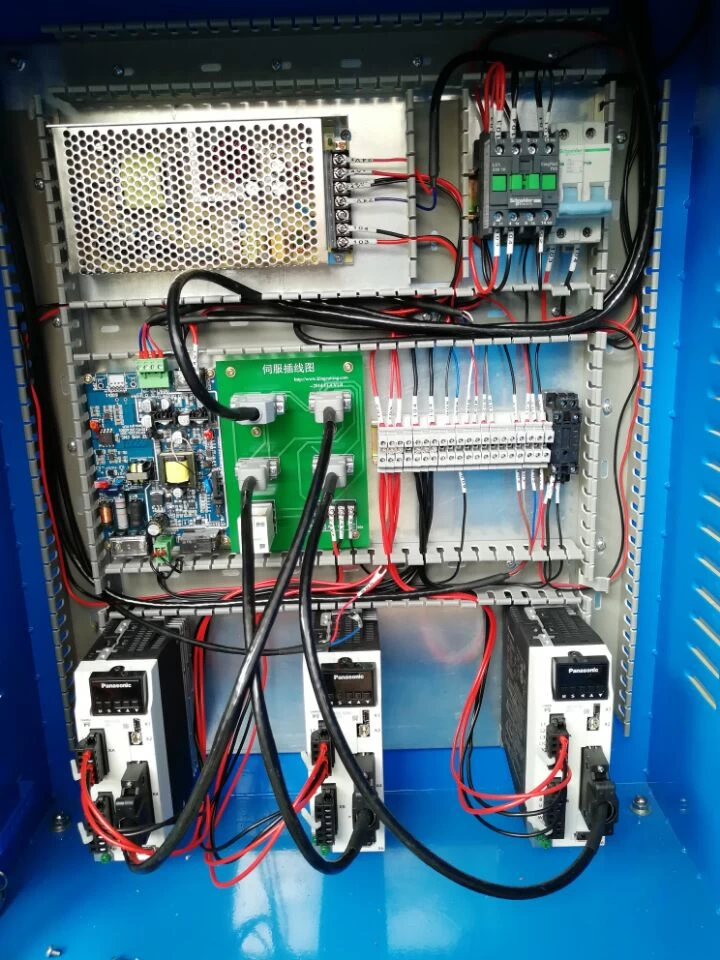

| CNC control system | Fangling F2300 |

| Effective cutting size | 1500*3000mm or customized |

| Cutting torch | Plasma or flame or both |

| Torch height controller | HYD Arc automatic THC for plasma, capacitive automatic THC for flame; electric |

| Driver and motor | Stepper or Servo |

| Gear box /Reducer | Planetary or Servo or Germany Neugart |

| Programming system | Fastcam, Starcam, IBE, SmartNest |

| Driving mode | Bilateral sides |

| Driving method | Rack and pinion |

| Cutting thickness | Plasma: according to the plasma power source; Flame: 6-180mm |

| Moving precision | 0.01mm/step |

| Fas fuel for flame cutting | Oxygen, gas, acetylene, propane, LPG |

| Weight | 1380KG |

Product features:

1.The synchronic double drivers are adopted in longitudinal linear guide track. More stable it tansfers, more precision it operates.

2.The light design of crossbeam has a good quality, light self-weight and small inertia.

3. The dust cleaning device is available, it is optional, we can insall dust clearing device for table plasma cutter as your kind requests. the whole machine has a compact structure.

1. Professional and patient service before and after sales, giving suggestions and advice.

2. Our own factory, control the production time and delivery time strictly.

3. Experienced workers, each process of the production is in high quality, ensure the total quality of the machine.

4. Choosing the best materials for the machines when producing.

5. Testing and commissioning after installed, make sure that there is no problem and machine run well.

6. Strong packaging, make sure that the machine will not be damaged during transportation.

7. Long term warranty, 18 months.

8. 24-hours after sales service, by Email, WhatsApp, Skype, Telephone, and Wechat etc.