- Browse Categories

- steel plate with pipe machine

- Table model cutting machine

- steel gantry cutting machine

- fiber laser cutting machine

- Multi-head cutting machine

- Portable Cutting Machine

- Subscribe

-

Get email updates on new products

- Certifications

-

- Contact Us

-

Tel: 0086 (0)27 87969255

Fax: 0086 (0)27 87413947

Whatsapp/wechat: 86 18064016480

Skype: berylxu1

E-mail: berylxu@kingcutting.com

- New Product

- News

-

-

Differences between the stepper and servo

Differences between thestepper and servo There is no qualityproblem on the domestic motor in CNC plasma cutting machine, and the precisionis the same ... -

difference between domestic laser machine and imported laser machine

Differences between domestic laser cuttingmachine and imported laser cutting machine The laser cutting machine is invented bywestern country, so many ... -

Introduction of Laser Technology

The AnalyticApplication and Introduction of Laser Technology When applying to thecutting, the laser technology provides very excellent cutting quality... -

How to choose and use plasma source

How to choose and use plasma source How to choose a most suitable plasma source is extremelyimportant for cutting quality,cutting speed,cutting effici... -

Guidline for portable type choice

Guidance for thePortable (Mini) CNC Cutting Machine Model Selection Nowadaysthere are many portable CNC cutting machine manufacturers in China, making... -

The Processing Standard and Power Supply Principle

The Processing Standardand Power Supply Principle The kerf processed by a high quality CNCplasma cutting machine should be with the following characte... -

Fiber Laser Cutting Machine

Brief Introduction ofFiber Laser Cutting Machine 1. Advantagesof fiber laser cutting machine 1.1 Excellentlaser beam quality: light spot is smaller... -

Indian Customers Visited Our Company

Indian CustomersVisited Our Company After a longtime preparation, our two Indian customers visited our company successfullyyesterday. After a ... -

Thailand customer visits our factory

Thailand customer Alex Visit our factory December 162019, the French group Delachaux Group Thailand Company Alex visited our company. This visit, ... -

How to choose right model cnc cutting machine

http://www.plasmacuttersupplier.com/index.html How to choose right model cutting machine To choose a most suitable CNC cutting machine,we need to cons...

-

- Follow us

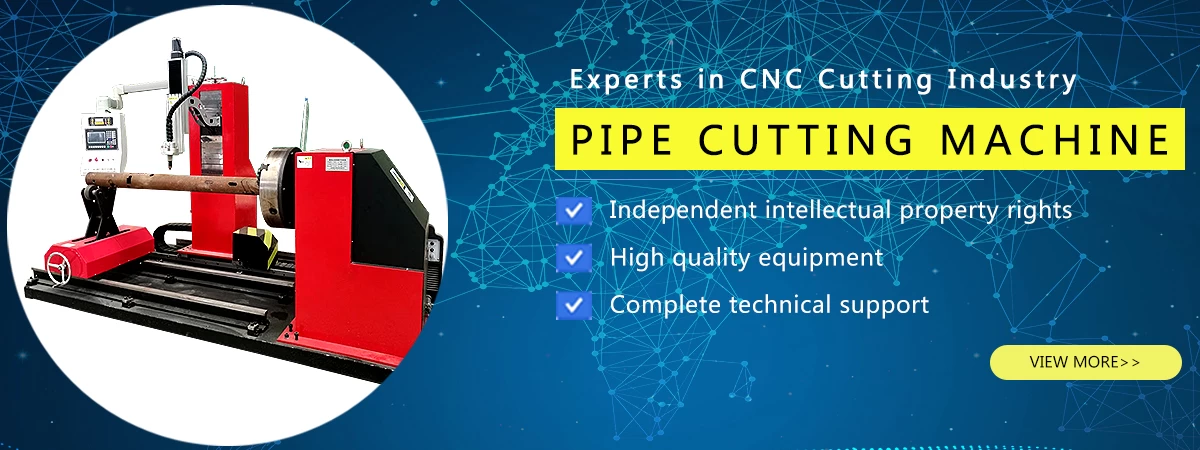

factory directly supply low cost high quality metal plasma tube cutter china supplier

- *. Effective Cutting Range: 59" × 118" (1500mm × 3000mm)

- *. Flame Cutting Gas: Oxygen + Acetylene / Propane/LPG

- *. Plasma Cutting Gas: Compressed air

- *. Max. Plasma Cutting Thickness: According to plasma cutter

- *. Max. Flame Cutting Thickness: 5-29/32" (150mm)

- *. Voltage: 110V/220V/380V/440V±10%, 50Hz/60Hz

- *. Power: 0.21HP (160W)

- *. Torch height controller: F1620 or SF30 Arc voltage automatic THC for plasma

- *. Nesting system: FASTCAM, StarCAM, SmartNEST

- *. Pipe cutting Diameter: 40-400mm

- *. Pipe cutting length: 0-12000mm

http://www.plasmacuttersupplier.com/about-us.html

factory directly supply low cost high quality metal plasma tube cutter china supplier

Effective cutting size can be customized: 1500*2000mm, 1500*2500mm, 1500*3000mm, 1500*4000mm, 1800*6000mm.

Oxy-fuel cutting up to 150mm

Shanghai Fangling F2100B stable system ,

Simple Menu Driven Operation ,

best cnc plasma cutter in china

Shape library with 40 shapes,

Easy enter shape dimmensions

Australia FastCAM : quick and easy column and row nesting ,

F1620 Arc voltage THC: AUTOMATIC MODE FOR CUTTING , AUTOMATIC PLASMA OPERATION ,Automatic initial height sensing

Linear rials for smooth , accurate motion .

Heat shield for pierce spatter protection

Portable , Economical , Easy to USE.

|

|

Model |

KCM-1530P |

|

1 |

Power source |

AC 220±10%VAC 50/60Hz |

|

2 |

Cutting mode |

O2/C3H8 or C2H2 |

|

3 |

Effective cutting range(mm) |

1300*3000 for metal sheets, 40--300mm diameter for tubes |

|

4 |

Input Voltage |

220V, 50HZ |

|

5 |

Length of tubes |

Max. 6000mm |

|

6 |

The ovality of tubes |

Less than 2% |

|

7 |

Cutting speed(mm/min) |

0-8000mm/min |

|

8 |

Cutting thickness(Flame) |

6-160 mm (O2/C3H8 or C2H2) |

|

9 |

Cutting thickness(Plasma) |

According to plasma source; |

|

10 |

Move precision |

±0.2mm/m |

|

11 |

Cutting system |

Shanghai Fangling control system |

|

12 |

Plasma source |

Huayuan brand 40A--160A |

|

13 |

Gas pressure(Mpa) |

Max.0.1 |

|

14 |

Oxygen pressure(Mpa) |

Max.0.7 |

|

15 |

Type of gas |

C3H8 C2H2 |

|

16 |

Emergency stop |

Yes |

|

17 |

Working temperature |

-5~45℃ |

|

18 |

Power |

8.5kw |

|

19 |

ARC |

Untouched arc striking |

|

20 |

Processing Materials |

Iron, steel aluminum sheets, galvanized sheets, Titanium plates and other kind |

Portable type Plasma Metal Pipe cutter machine, CNC metal tubecutting machine can cut various tube and plate, it can cut mild steel withflame cutting, and carbonsteel, stainless steel,aluminum,copper and other non-ferrous metal with Plasma cutting;can configurate as your required, thus it is widely applied in industries suchas machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotiveetc.

Automatedgas cutting machine functions and a user-friendly CNC system has 45 differentcutting path settings and any plane shape composed of beeline also can beprogrammed. Precision and solid guide rails and accuracy motion controlmakes the machine can precisely cut the shape as customers’demand

1. Professionaland patient service before and after sales, giving suggestions and advice.

2. Our ownfactory, control the production time and delivery time strictly.

3. Experiencedworkers, each process of the production is in high quality, ensure the totalquality of the machine.

4. Choosing thebest materials for the machines when producing.

5. Testing andcommissioning after installed, make sure that there is no problem and machinerun well.

6. Strongpackaging, make sure that the machine will not be damaged duringtransportation.

7. Long termwarranty, 18 months.

8. 24-hoursafter sales service, by Email, WhatsApp, Skype, Telephone, and Wechat etc.