The Processing Standard and Power Supply Principle

The Processing Standardand Power Supply Principle

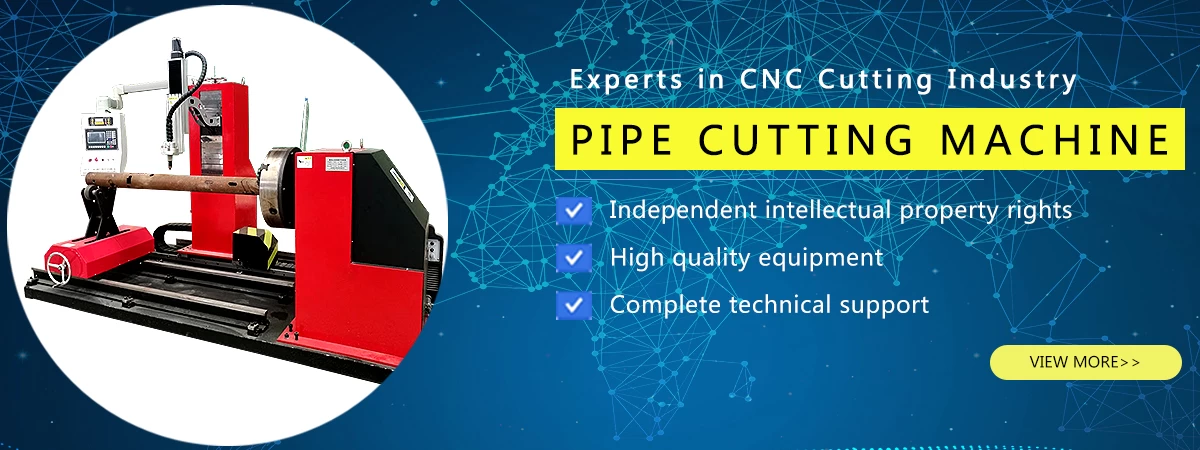

The kerf processed by a high quality CNCplasma cutting machine should be with the following characteristics: narrowslit, the cut section should be rectangular, bright and clean kerf surface, noslag or dross, and the surface hardness doesn’t affect later machining. Inorder to make users understand the working characteristics of the plasmacutting machine power, Wuhan Kaierbei CNC introduces some relevant knowledge ofworking principles of the plasma power source.

1. There aremainly 3 kinds of plasma cutter, semi-dry plasma, dry plasma and underwaterplasma. From cutting quality, the plasma cutting machine can be divided into: ordinaryplasma, fine plasma and laser plasma.

2. Semi-dryplasma cutting is also called wet type plasma cutting and water-cooled cutting.The wet type plasma cutting uses the high temperature sprayed from the nozzleto ionize the high speed air flow, then formed electric conductor. When thelarge current flows, the water cooled cutting air flow formed into hightemperature plasma arc, and the heat of the plasma arc melt the metal on thekerf of the work piece. Water cooled cutting is a kind of processing methodthat uses the high speed plasma to flow the melt metal away. The water cooledcutting uses the slender and stable plasma arc formed from annular airflow,ensuring economically and stably cut any conductive metal.

3. Dryplasma cutting is also called air cooled cutting, uses the air compressorspraying air to the plate kerf for cooling, this kind of cutting cost is verylow, but the contamination is heavy.

4. There isno levorotatory or dextral for ordinary plasma. There is high frequencyprotection for the cutting torch and hose bundle, the dynamic perforation isthe start of the dynamic cutting, there is no need to set the reference point. Theplasma torch quick setting can realize the plasma gouging. And the soft start-upcircuit design ensure the long service of vulnerable parts like electrode andthe nozzle.

Theusing of the plasma cutting machine, is relating to the plasma generator, alsocalled the plasma power source. Compared with traditional manual plasma cutting,the power of CNC plasma cutting machine is different in the working principleand cutting material thickness. The machine plasma power source applies tostainless steel, cast iron, copper, aluminum and other nonferrous metal plateand the steel plate under 6mm thickness, mainly used for plane cuttingirregular figure, and in theory, can cut the figure whatever draw by AUTOCAD.(But the figure with radius less than 2 times of the plasma cutting slit widthcannot be cut.)

Amongthe cutting methods, plasma cutting has more widely cutting scope and higherefficiency than ordinary gas cutting. This makes plasma cutting technologygradually developing to CNC from manual or semi-automatic cutting, and becomeone of the main directions of the CNC cutting technology. Along with theimprovement of the CNC plasma cutting technology in recent years, there aremany factories began to develop the CNC plasma cutting equipment, but thequality are not all good, mainly show on the cutting quality. The kerf finish,cutting surface smoothness, slit width and the cutting tolerance are different.So in order for the users to choose plasma cutting equipment, Wuhan KaierbeiCNC gives you some tips about the plasma cutting kerf quality.

Whenwe evaluate the kerf quality, mainly on the kerf width, kerf perpendicularity,kerf surface smoothness, kerf texture depth, kerf bottom dross, heat affectedarea hardness on the kerf and the width. The surface quality of the plasma arcis between that of the oxygen-acetylene cutting and band saw cutting. If thesteel plate is over 100mm, the low cutting speed caused more melted metal, sothe kerf is rough.

WuhanKaierbei CNC Technology developed KC series CNC plasma cutting machine, usingthe CNC system to control the plasma arc to cut. The plasma arc cutting is touse the heat of high temperature plasma arc, making the kerf of the work piecemelted, and high speed plasma blow out the melted metal to form kerf. Since thecutting speed is fast and good cutting quality, the CNC plasma cutting machinewill replace most of the manual plasma cutting, manual flame cutting machineand CNC flame cutting machine.